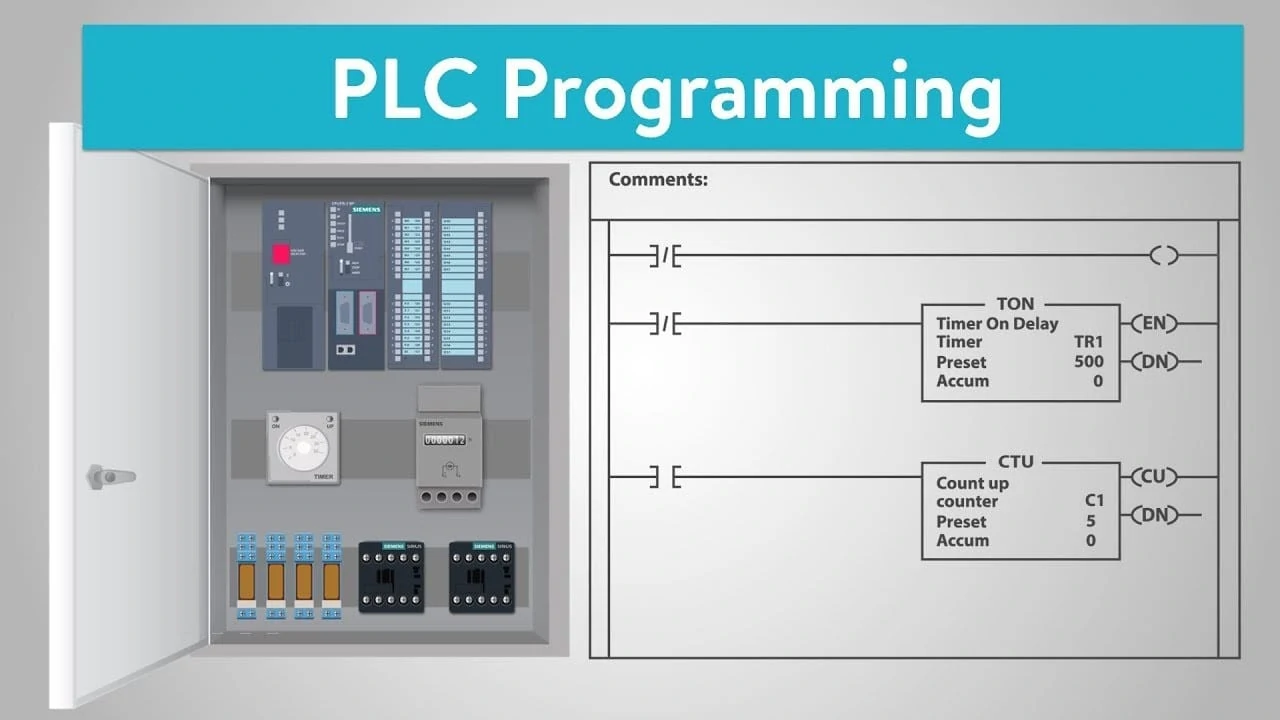

Introduction to PLC Programming

Programmable Logic Controllers (PLCs) are industrial digital computers designed to control manufacturing processes, machinery, and automation systems. PLC programming is the process of creating instructions that dictate how a PLC should operate to automate industrial tasks efficiently.

PLC programming is essential in industries such as manufacturing, automotive, food processing, and energy management. It helps improve productivity, reduce human error, and enhance system reliability.

How PLC Programming Works

PLCs receive input signals from sensors, switches, and other devices, process the data based on the programmed logic, and then send output signals to control actuators, motors, valves, and other machinery.

Key Components of a PLC System

-

Input/Output (I/O) Modules – Connect sensors and actuators to the PLC.

-

Central Processing Unit (CPU) – Executes the control program.

-

Memory – Stores the program and data.

-

Power Supply – Provides power to the PLC system.

-

Programming Device – A computer or handheld device used to write and upload programs.

Popular PLC Programming Languages

The International Electrotechnical Commission (IEC) standard IEC 61131-3 defines five PLC programming languages:

-

Ladder Logic (LD) – The most common language, resembling electrical relay logic diagrams.

-

Structured Text (ST) – A high-level language similar to Pascal or C.

-

Function Block Diagram (FBD) – Uses graphical blocks to represent functions.

-

Instruction List (IL) – A low-level, assembly-like language.

-

Sequential Function Chart (SFC) – Used for complex processes with sequential steps.

Steps to Write a PLC Program

-

Define the Control Requirements – Understand the machine or process to be automated.

-

Choose the Right PLC – Select a PLC based on I/O requirements and processing power.

-

Develop the Logic – Write the program using the appropriate language (e.g., Ladder Logic).

-

Simulate and Test – Use simulation software to verify the program before deployment.

-

Download to PLC – Transfer the program to the PLC and test it in a real environment.

-

Monitor and Troubleshoot – Continuously check for errors and optimize performance.

Applications of PLC Programming

-

Manufacturing Automation – Assembly lines, robotic control.

-

Traffic Light Control – Managing signal timings.

-

HVAC Systems – Regulating temperature and airflow.

-

Water Treatment Plants – Controlling pumps and filtration systems.

-

Packaging Machines – Ensuring precise filling and sealing.

Advantages of PLC Programming

✔ Reliability – PLCs are robust and work in harsh industrial environments.

✔ Flexibility – Programs can be modified without hardware changes.

✔ Scalability – Additional I/O modules can be added as needed.

✔ Ease of Troubleshooting – Built-in diagnostics help identify issues quickly.

Conclusion

PLC programming is a critical skill in industrial automation, offering efficiency, precision, and control over complex processes. Whether you’re a beginner or an experienced engineer, mastering PLC programming opens doors to opportunities in various industries.

By learning Ladder Logic, Structured Text, or other PLC languages, you can design and implement automation solutions that enhance productivity and reduce operational costs.

Would you like recommendations for PLC programming courses or software tools? Let us know in the comments!

Visit our website: